Metal 3D Printing Gallery

Some of the complex components produced using Metal 3D Printing technology at Rapid DMLS

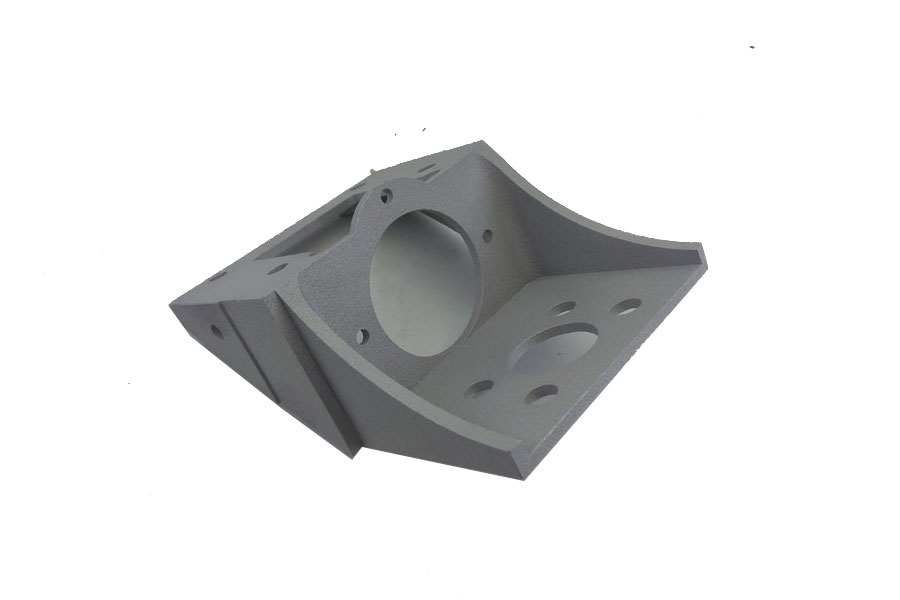

- Part Name: Bracket

- Material: Aluminium AlSi10Mg

Why 3D Printing: To counter the long waiting time for imports of spare parts for the MIG and Sukhoi Aircrafts, this part was 3d printed and was supplied in a week’s time.

- Part Name: Brackets

- Material: Stainless Steel 316L

Why 3D Printing: To demonstrate that the Strength to Weight ratio of a 3D printed part is superior to that of a CNC machined part.

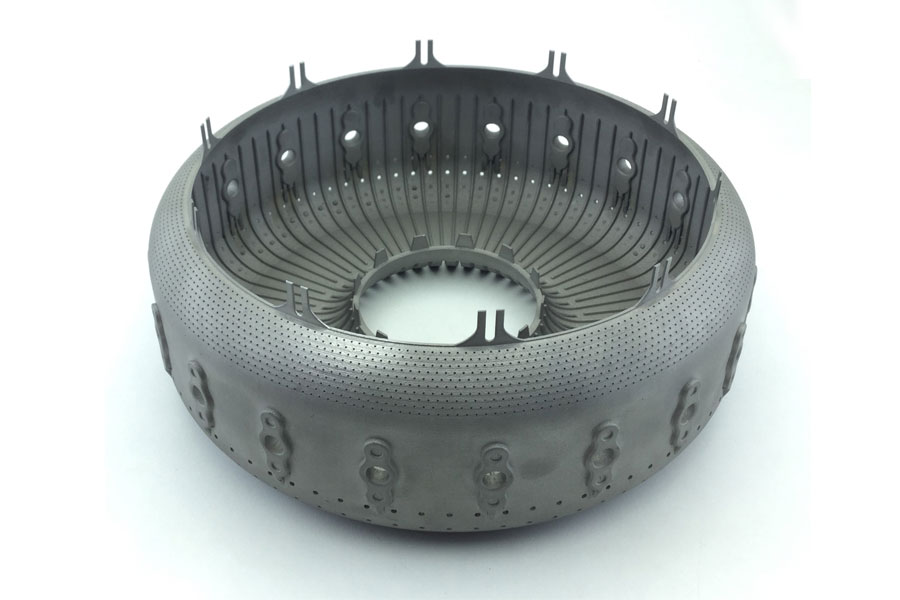

- Part Name: Combustion Chamber

- Material: Inconel 718

Why 3D Printing: To realise a monolithic design with reduced weight.

- Part Name: Conformal Cooled Insert

- Material: Maraging Steel 300

Why 3D Printing: The designed cooling channels can be manufactured only through 3D printing. The cooling channels are designed so that the pressure die casting cycle time reduces thereby increasing the process productivity.

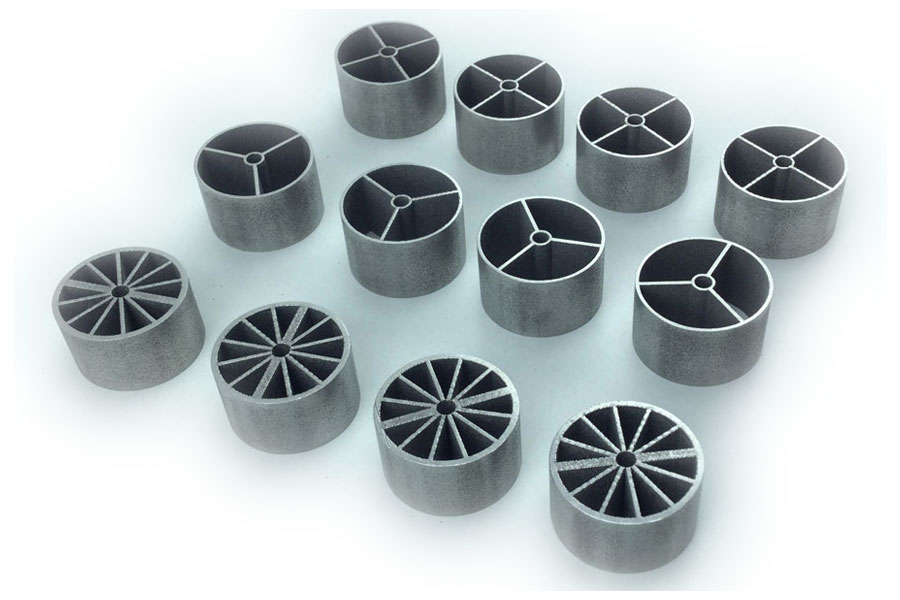

- Part Name: Custom Wheels

- Material: Aluminium AlSi10Mg

Why 3D Printing: Mass Customisation. 3 unique designs were printed together at once and the best performing design was selected.

- Part Name: Deform Nuts

- Material: Stainless Steel 316L

Why 3D Printing: The design is not made for functionality rather than design for manufacturability. Due to the ductility of 316L, the nuts deform as per the functionality under the given loads.

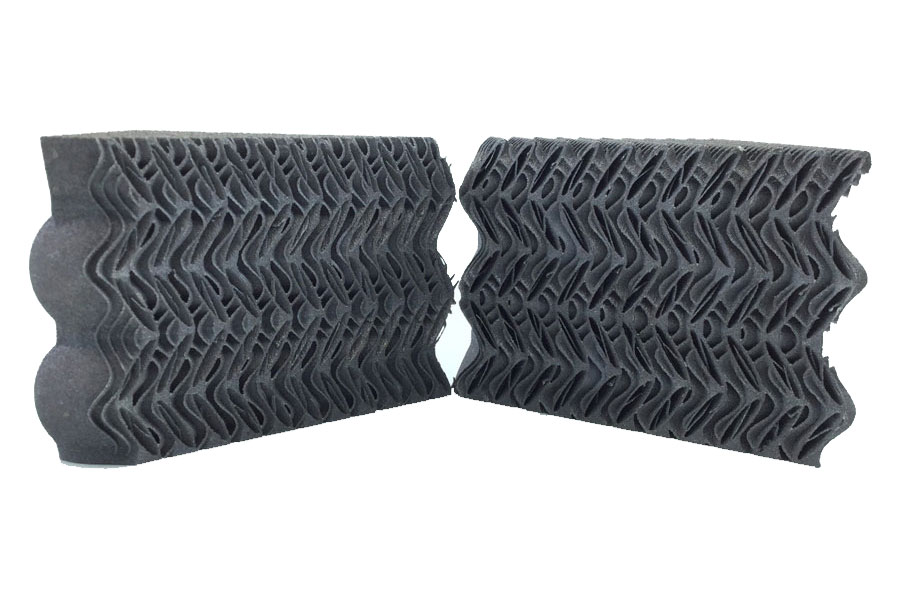

- Part Name: Heat Exchanger

- Material: Aluminium AlSi10Mg

Why 3D Printing: The convoluted interior profiles achieved through 3D printing increases the surface area for heat transfer which expedites the cooling process.

- HP Nozzle Guide Vane

- Material: Inconel 718

Why 3D Printing: The part has numerous cooling holes which can be achieved directly through 3D printing, unlike the traditional process with multiple operations.

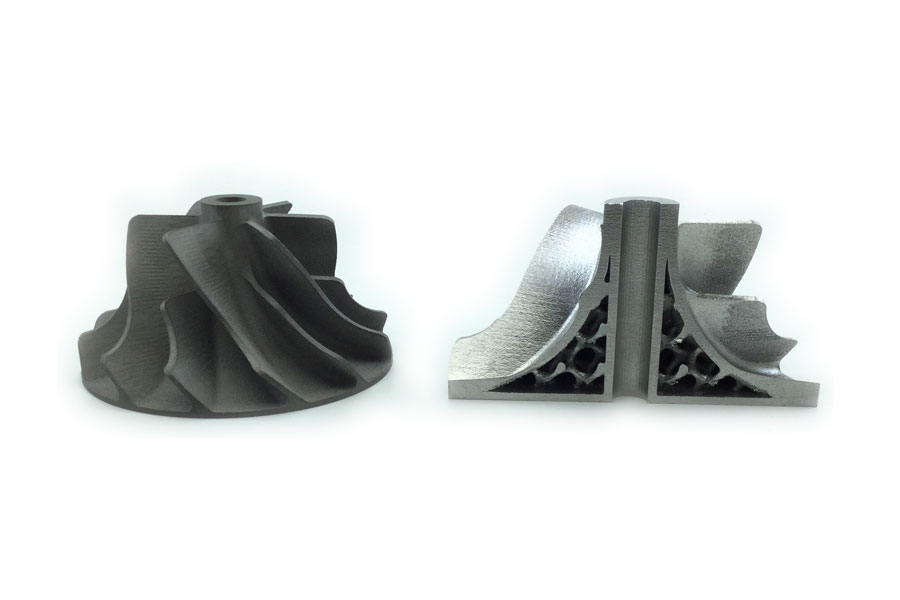

- Part Name: Impeller

- Material: Stainless Steel 17-4PH

Why 3D Printing: Weight of the impeller is reduced without compromising on the strength and functionality.

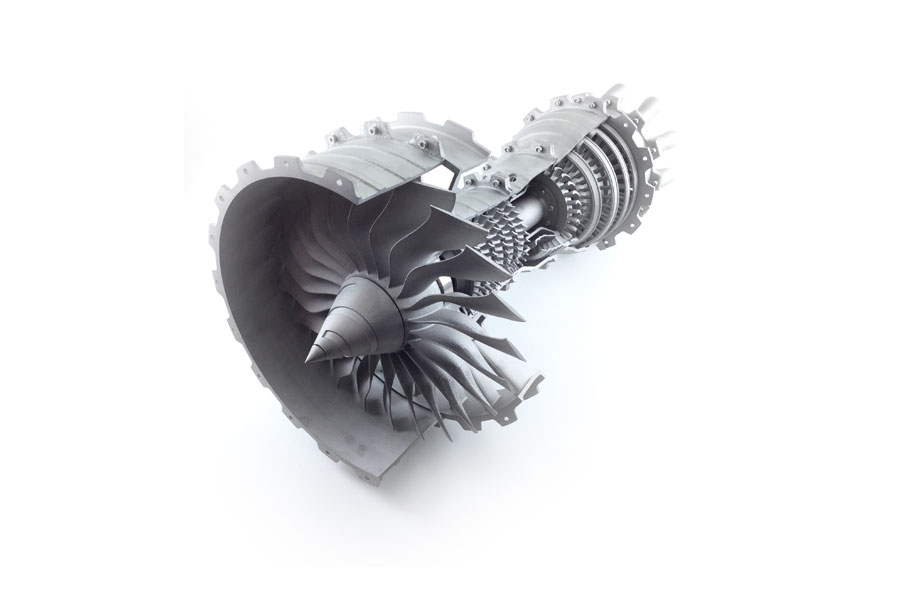

- Part Name: Jet Engine Prototype

- Material: Stainless Steel 316L

Why 3D Printing: To show that however complicated the parts are, the entire assembly can be manufactured with faster timelines.

- Part Name: Hydraulic Manifold

- Material: Stainless Steel 17-4PH

Why 3D Printing: The additive design increases the efficiency of the manifold by reducing the pressure losses of the fluids.

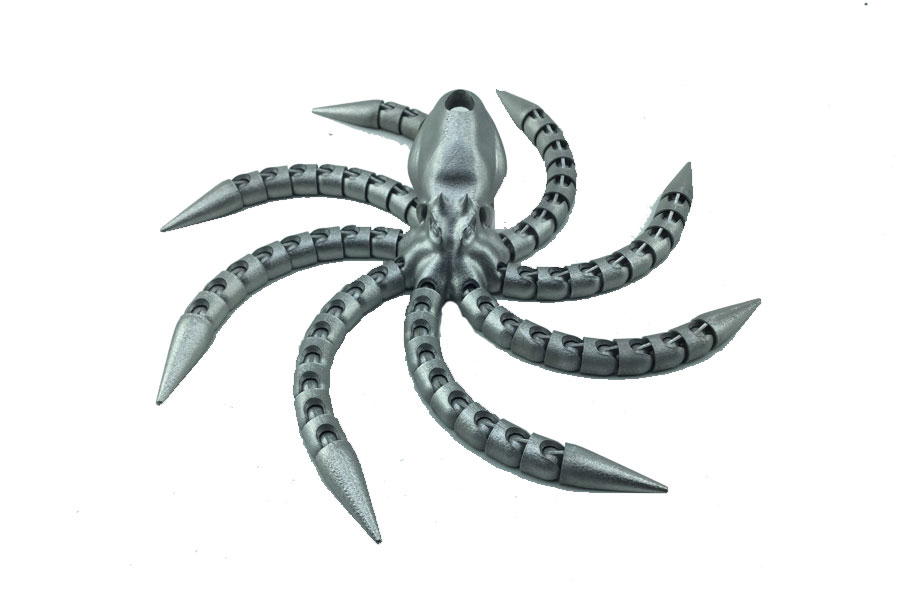

- Part Name: Octopus

- Material: Stainless Steel 17-4PH

Why 3D Printing: The entire part is as-built and not assembled. The tentacles of the octopus are free to move which shows the freedom of design involved in the process.

- Part Name: Range Detector

- Material: Aluminium AlSi10Mg

Why 3D Printing: Parts with small batch quantity and complex profiles are best suited for 3D printing.

- Part Name: Wave Guide

- Material: Aluminium AlSi10Mg

Why 3D Printing: It is printed as a monolithic piece, instead of the earlier conventional designs which needed numerous parts to be fastened together to constitute the main part.